the best Manufacturers and Suppliers in China

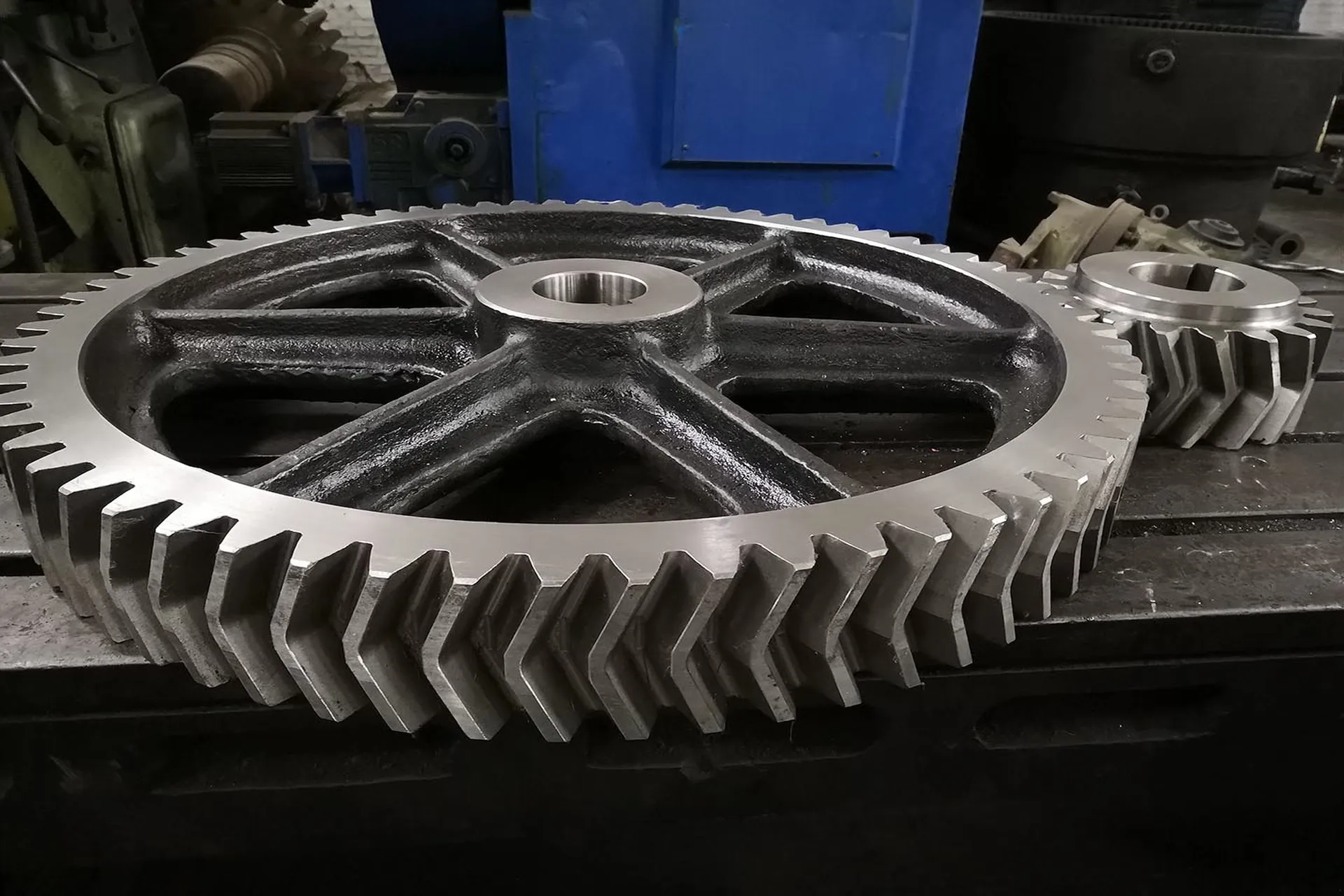

Manufacturer Of Herringbone Gears

Advantages of Herringbone gear

Herringbone gears operate quietly.

Herringbone gears offer smooth power transmission.

Due to the V shape, the axial thrust as produced in helical gears is canceled out.

Limitations of Herringbone gear

Due to their design, manufacturing is complicated.

Herringbone gears are expensive.

Herringbone gear Ssliding contact between teeth results in friction and heat generation.

Herringbone Gear Specification

Circular pitch(CP)

Diametrical pitch

Module(mod or M)

Pressure angle

Mounting Specifications

Materials

High-quality Prducts

Herringbone gears, also called double helical gears, are gear sets designed to transmit power through parallel or, less commonly, perpendicular axes.

China Suppliers Carbon Steel

Details

- The thrust force produces by each half of the gear is equal and opposite in direction, and thus they cancel out each other.

- The absence of thrust force allows the use of a higher helix angle (up to about 45°).

- It can transmit very high mechanical power or torque.

- Herringbone gear is expensive because of its complicated design and manufacturing.

High Class Customized Forging Steel

Details

- Material: Carbon Steel, Alloy Steel

- Diameter of Gear Wheel: MAX 13 000 mm

- Workplan: Forging, Casting, and Welding

- Gear Teeth treatment: Surface hardening cemented and quenching

Customization Forging Steel High Precision

Details

- Maximum Helix Angle: ±45°

- Maximum O.D : 2500mm

- Maximum Diametral Pitch: DP 1

- Maximum Module: 45 mm

Large Diameter Alloy Steel

Details

- The modulus m of large herringbone gear shall be between 28-36mm;

- The helix angle of herringbone gear shall be controlled between 20-28 °;

- The tooth surface hardness of large herringbone gear should be controlled between 240-280hb;

- The error between the standard regular lines of the left and right herringbone gears should also be controlled. Generally, the standard average line error should be less than 0.1mm.

OEM Customized High Quality

Details

- Hobbing: Hobbing machines can be manufactured today to machine herringbone teeth in gears up to 5.6m in diameter.

- End Milling: Herringbone gears with a large diameter are generally better suited for end milling.

- Shaping: another suitable method to cut teeth on herringbone gears, provided they are continuous and contain a center slot

High Precision Anti-corrosive Steel

Details

- Materials: C45,40Cr,20CrMnTi,42CrMo, Copper, Stainless steel, and so on as per your requests.

- Processing: Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment…

- Heat Treatment: Carburizing, Induction, Flame, Nitriding…

- Application: heavy machinery,heavy-duty vehicles

Materials Used

We use high grade handpicked materials to make sure that each and every herringbone gears that we design and manufacture are absolutely state of the art. Some of the materials that we use include alloy steel, stainless steel, aluminum, brass, carbon steel, gray cast iron, bronze and ductile iron. We also incorporate a number of non-metals in the production of herringbone gears. These non-metals include plastic, nylon, acetal, phenolic, Delrin, polycarbonate and polyester. Each of these materials are procured from the finest resources and do not include any impurities. This makes the herringbone gears highly reliable and efficient for a broad range of applications. We also expose all herringbone gears to diverse processes such as die forming, heat-treating, finishing and machining which make them excellent and highly functional.

Gear Comparison

Difference between helical gear and herringbone gear

| Helical Gear | Herringbone Gear |

|---|---|

| Teeth of the helical gear are cut in the form of a helix (either left hand or right hand helix) on the cylindrical gear blank. | Identical teeth are cut in two halves of the gear blank maintaining same module, number of teeth and helix angle but opposite hand of helix. |

| A pair of mating helical gears produces significant radial thrust force. | Thrust force produces by each half of the gear is equal and opposite in direction; and thus they cancel out each other. |

| Radial thrust force limits the helix angle to a maximum of about 25°. | Absence of thrust force gives the provision to use higher helix angle (up to about 45°). |

| Bearings that can handle both axial load and thrust load are required to use with helical gear. | Since thrust force does not exist, so bearings that can handle heavy radial load can be used with herringbone gear. |

| Power transmission capability of helical gear is comparatively small. | It can transmit very high mechanical power or torque. |

| Design and manufacturing of helical gear is easier and thus it is cheap. | Herringbone gear is expensive because of complicated design and manufacturing. |

Similarities between double helical gear and herringbone gear

- In both the cases, two helical gears must have same module, same number of teeth and same helix angle but opposite hands of helix.

- Both gears are capable of eliminating thrust force on bearings. So their purposes are same.

Applications of Herringbone gear

Applications of Herringbone gear include transmission of high torque, heavy machinery, gas turbines, heavy-duty vehicles, torque gearboxes, etc. Apart from these, some of the other uses of these Herringbone gears include :

- On heavy machinery

- For external gear pumps

- In applications that typically need higher pressures and larger percentages of filled material

Machining Herringbone Gears

An effective cutting process for a herringbone gear typically involves hobbing, milling, and shaping, though these methods depend largely on whether or not a gap is required between the two helixes or if the herringbone is to be continuous.

1) Hobbing

2) End Milling

3) Shaping

Get In Touch

Our premium herringbone gears are manufactured to your individual design specifications. These gears offer the same benefits as single helical gears with increased strength and durability.